INDUSTRIAL

Solutions for Laser Cleaning Welding Texturing Marking

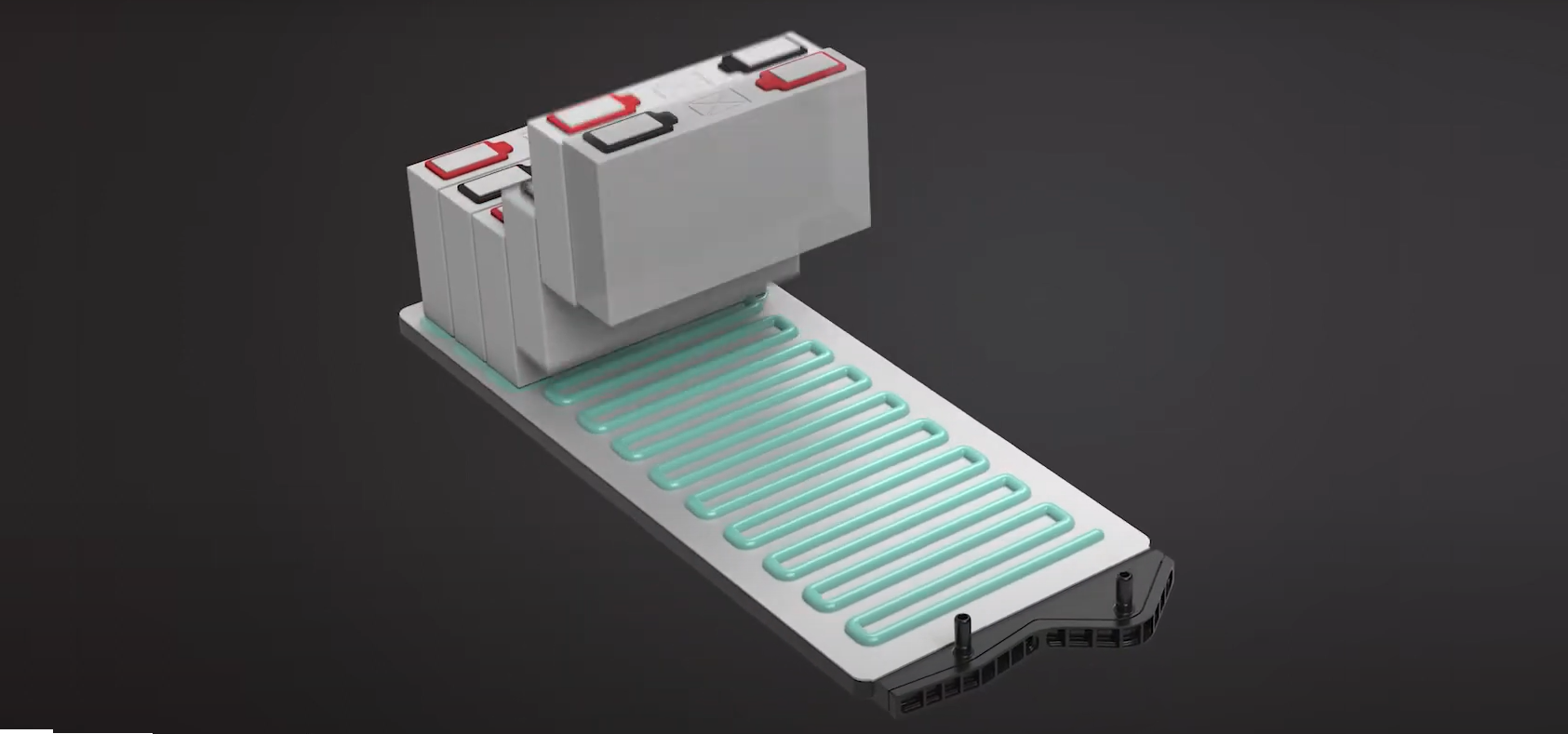

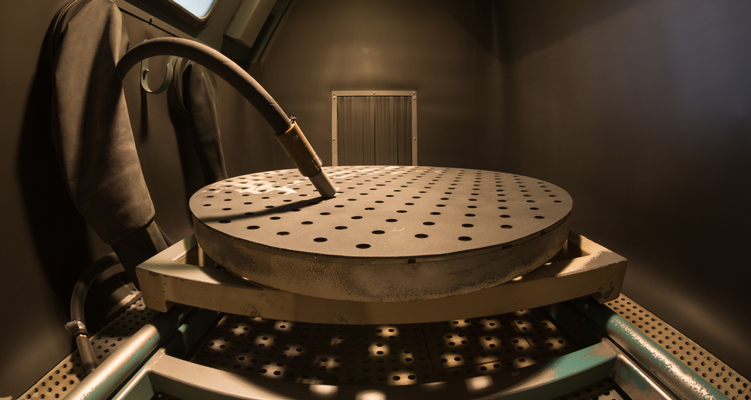

Laserax works with the world’s leading manufacturers to implement automated laser cleaning, welding, texturing, and marking solutions. Providing turnkey machines and OEM systems, the driving force behind Laserax is the desire to push the limits of laser technology and establish new standards in the industry.

-

![Innovative Processes]()

Innovative Processes

-

![Inline Solutions]()

Inline Solutions

-

![Guaranteed Safety]()

Guaranteed Safety