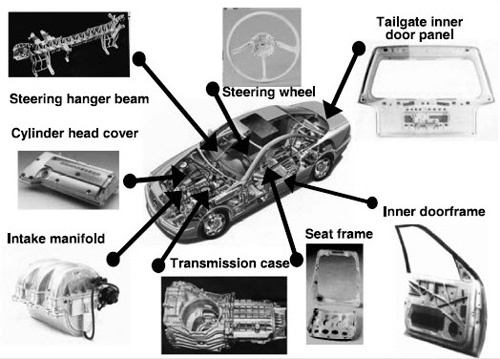

Magnesium alloys have many characteristics that makes them interesting alternative to steel and aluminum in the automotive industry. Other characteristics generate inconveniences that makes magnesium a less obvious choice. In the excellent articles by Total Materia: "Automotive Uses of Magnesium Alloys: Part One and Part Two", you will find characteristics, applications and measures used to compensate magnesium drawbacks.

A combination of light weight, high specific strength, and good castability makes magnesium alloys a promising engineering material for the automotive and aerospace industries. Mg-Al-based alloys, especially the AZ and AM series, combine good room-temperature strength and ductility with satisfying salt-spray corrosion resistance and excellent castability.

extract from: Automotive Uses of Magnesium Alloys: Part One

Laser marking machines can be used to provide cradle-to-grave permanent identification of metal parts. Laser markers allow complete product traceability of most metallic parts throughout the supply chain, from casthouses to final disposition of the product.

Title photo credit: Total Materia , Automotive Uses of Magnesium Alloys: Part One