Laser technology offers a wide range of possibilities, ranging from harmless laser pointers to extremely powerful laser marking and cleaning systems. Some lasers are powerful enough to damage your skin, cause serious eye injuries, and set your workplace on fire. This is why governmental and international organizations have put in place strict standards separating laser systems into safety classes according to their ability to cause hazards.

Do you need an integrated machine or an OEM system?

Before we go on, what’s a laser? The term was coined in 1959 by Gordon Gould, an American physicist, and the word itself is an acronym for “light amplification by stimulated emission of radiation.” Through optical amplification, laser systems produce highly concentrated light beams that are rich in energy.

Laser Classes Explained

In this article, we’ll go over the different laser standards and laser hazards. But first, what are the different laser classes? And what distinguishes one class from another?

For simplicity’s sake, we’ll focus on the revised laser classification system specified in the IEC 60825-1 international standard. In the United States, ANSI Z136.1 (the old system) is still used and is very similar.

Class 1 Lasers

Class-1 lasers are safe for the eyes in all operations even for a long time and with optical instruments. These lasers usually possess a very low output power (a few microwatts).

Industrial marking systems of higher classes (such as class 3 or 4) are often reduced to class 1 by safely enclosing them (this is called an embedded laser). For example, laser printers use class 4 lasers enclosed in the printer. As such, they’re considered class 1 laser products and you don’t need to take precautions during normal operations and as long as they’re not damaged.

Examples of class 1 laser products:

Class 1M Lasers

Class 1M lasers (or, class 1 “magnified”) are much like class 1 lasers since they’re generally safe for viewing with the naked eye.

So what differentiates them from class 1 lasers?

Viewing their magnified beam with optical instruments like binoculars may be hazardous (this excludes prescription glasses). Because the beam is amplified, it exceeds the maximum permissible exposure (which is the maximum power density considered safe for viewing).

Laser diodes, fiber communication systems, and laser speed meters are class 1M lasers.

Class 2 Lasers

The blink reflex normally prevents viewing dangerous (and visible) wavelengths for longer than 0.25 seconds. As long as you’re not fighting your instincts, the laser beam is safe for viewing. It can only cause eye injuries if you intentionally stare at it.

Lasers can only be classified as class 2 if their laser light is visible. This is important because the blink reflex as well as other aversion responses (like head movements) won’t be triggered otherwise.

Class 2 lasers are typically limited to 1 mW for continuous-wave lasers (but it could be more in certain contexts). In the old classification system, class IIa lasers are a subclass that are only harmful if the exposure duration exceeds 1000 seconds

Class 2M Lasers

Class 2M lasers are generally safe. As with class 2 lasers, the blink reflex will protect your eyes from unmagnified beams. But if you view the beam using an optical instrument (even accidentally), the blink reflex won’t be enough to prevent eye injuries. Even the shortest exposure time can be harmful.

Class 3R Lasers

Class 3R laser systems like laser pointers and laser scanners pose a higher safety risk than previous classes, but they’re still considered safe when handled carefully. Eye injuries may occur if you directly view the beam—especially when using optical instruments. But generally speaking, a brief eye exposure won’t harm your eyes (the acceptable exposure time varies according to the wavelength).

Since exposure to the beam is low risk but potentially hazardous, class 3R laser products must be identified with appropriate warning labels (this is also true with higher laser classes). If you’re using the old classification system, you’ll find that class IIIa lasers (or class 3a) are essentially the same.

Class 3B Lasers

Direct contact with the laser beam or specular reflections (also known as mirror-like reflections) of 3B lasers must be avoided. They may cause eye injuries or small burns on the skin.

Only diffuse reflections are safe with class 3B lasers.

To get an idea of the maximum emissions permitted for class 3B lasers, take a look at the following accessible emission limits (AEL):

- Continuous-wave lasers cannot exceed 0.5 watts if their wavelength is between 315 nm and the far infrared

- Pulsed lasers cannot exceed 30 millijoules if they’re within the visible laser light range (between 400—700 nm)

Entertainment light shows fall into this category. If you’re using the old classification system, class 3B is the same as class IIIb.

Class 4 Lasers

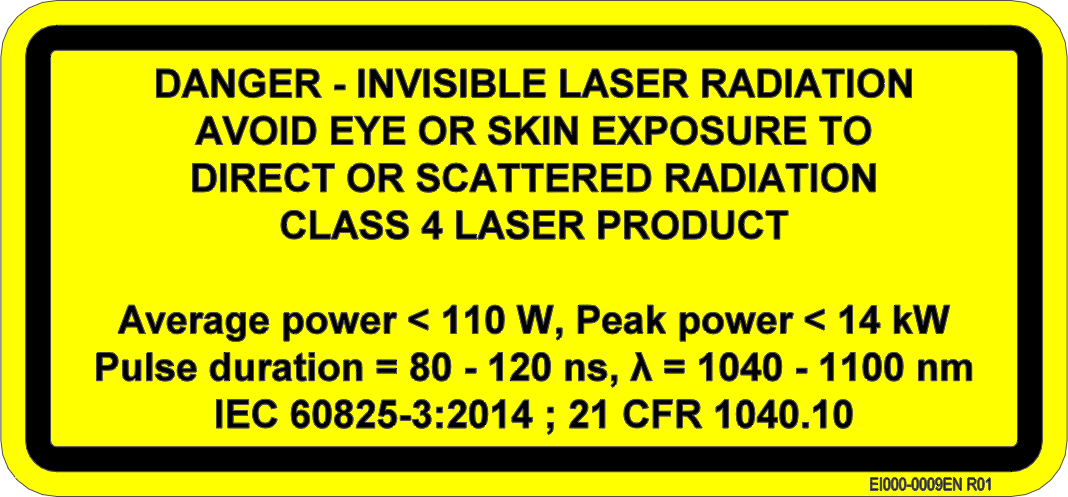

Class 4—the most dangerous lasers. Proceed with extreme caution if the laser is not properly enclosed.

The output power of class 4 laser products is so high that they can ignite materials. That power is what makes them attractive for laser cutting, laser marking, laser welding, and laser cleaning.

Class 4 is the highest class in terms of laser hazards. If you’re within the hazard zone, you’re exposed to severe eye and skin injuries. In addition, combustible materials shouldn’t be in the laser’s surroundings to avoid fire hazards.

Diffuse reflections of class 4 lasers are also hazardous. You could get sunburns or lose sight simply by looking at a workpiece being processed.

A good rule of thumb is to pay attention to warning labels, wear protective equipment if required, and follow any additional control measures for laser safety.

Fortunately, class 4 lasers can be properly enclosed to render them essentially harmless. For example, automated laser marking machines manufactured by Laserax are class 1 laser products, but they include high-power laser systems that range from 20 watts to 500 watts.

Now that you have a good idea of the degree of danger of each laser class, let’s look at the types of dangers.

The Different Laser Hazards

Laser radiation can cause three basic types of laser hazards: eye, skin and fire hazards.

If a laser system is not class 1 compliant, workers should wear protective equipment when entering the danger zone: laser safety glasses for eye protection, and special suits for skin protection.

Eye Injuries

From all the laser hazards, eye injuries are the most serious. Losing sight is no small thing. Let’s explore why eye injuries occur and how you can prevent them.

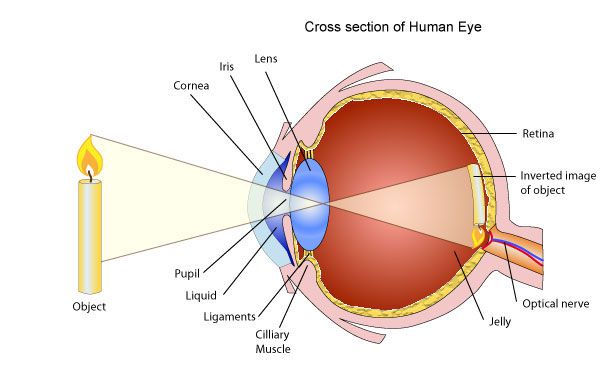

When light reaches the eye, the cornea and the lens act as amplifiers. Like a magnifying glass, they concentrate light onto the retina (the back of the eye) which, afterward, is processed by the brain as an image. Those three components of the human eye (cornea, lens and retina) are the most susceptible to damage from laser radiation.

All types of laser lights can harm your eyes, but the various components of the human eye react more strongly with some light wavelengths. Most laser engraving machines produce light in the near infrared (700-2000 nm) and the far infrared (4000 nm - 11,000 + nm) spectrum—all of which are invisible to the human eye.

Part of visible light is absorbed by the eyes before being amplified by the lens and cornea. This protects you by reducing the output power of light.

But infrared light isn’t visible and isn’t absorbed by the eyes. When invisible light reaches the retina, it’s more powerful and more dangerous than visible light.

All this energy is spent burning a small area of the retina which causes blindness and severe eye damages. Photochemical damage is also possible for wavelengths lower than 400 nm (in the ultraviolet range) and may cause cataracts (decreased vision).

Protective eyewear like laser goggles protect you by absorbing dangerous light. Different goggles absorb different wavelengths, so you need to wear the right goggles for your laser system. For example, you need goggles that protect you against the 1064 nm wavelength for the Laserax fiber laser systems.

Skin Hazards

If you had the choice between putting your eyes or your hands on the stove, chances are you would put your hands. With this in mind, it’s easy to understand why skin injuries are less serious than eye injuries. But the risks of skin burns still deserve your attention.

Direct contact with the laser beam and specular (mirror-like) reflections can cause skin injuries. Those injuries are typically caused by thermal damage similar to touching the stove, or photochemical damage like sunburns. The burn level depends on the laser’s output power, the wavelength, the size of the affected area, and the duration of the irradiation.

Fire Hazards

Apart from health hazards, laser light can also start fires and put your work environment at risk.

Only class 4 lasers pose real fire safety concerns. Their direct beam as well as any types of reflections can ignite combustible materials. For a safe integration, those lasers must be enclosed properly and account for all possible angles of reflection, including diffuse reflections.

Overview of Laser Standards

Laser standards were first put in place when scientists recognized that even low-power lasers could be potentially dangerous. They provide appropriate laser safety measures to prevent health and fire hazards.

All standards explain the different classes, how to calculate certain laser parameters, the proper labels, safety measures when handling the laser, and so on. They also enforce safety measures like the nominal hazard zone, which defines where direct laser light, specular reflections and diffuse reflections are dangerous.

Laser standard resources:

- The international standard for laser classification is IEC 60825-1.

- The North American equivalent of this standard is ANSI Z136.

- In the United States, the FDA regulates laser products with Code of Federal Regulations Title 21 (also known as 21 CFR 1040).

- The FDA has published Notice 50 in 2007 and Notice 56 in 2019, stating they don’t object to laser products that conform with IEC 60825-1.

Before You Buy a Laser

When you buy laser products, you should either get a class 1 laser machine or work with integrators who make sure your class 4 laser system is class 1 compliant. Here at Laserax, laser experts offer guidance to make sure all products are 100% laser safe, including laser fume extraction.

For a quick overview of the laser safety classes, you can consult our laser safety classification table.