In today’s manufacturing, direct part marking takes an important place. 2D data matrix codes, serial numbers, and 1D barcodes are often mandatory to implement traceability for plastic and metal parts. These are often considered safety critical or of high value.

Manufacturers who need permanent markings for traceability typically have two options: dot peen marking or laser marking. Between these two technologies, the choice is not always easy. To understand which one is a better option for your marking needs, we’ll go over their respective strengths and weaknesses in this article.

- Overview of Dot Peen Marking Machines

- Overview of Laser Marking Systems

- The Difference Between Dot Peen and Laser Marking

Overview of Dot Peen Marking Machines

Dot peen marking machines, also known as pin stamping or pin marking machines, use small pins made of a rigid material, such as carbide or diamond, to locally indent the parts to be marked. By hitting the surface with these pins, dot peen machines leave small holes that permanently change the part’s roughness and visual aspect.

The pin’s movements and force of impact can be ensured by two types of systems.

- Pneumatic dot peen markers move the stylus using compressed air, providing a stronger impact to mark harder materials like steel. One of the downsides of this option is the need for an additional utility for the compressed air.

- Electromechanical systems move the stylus using electromagnetic force. They provide increased precision compared to pneumatic machines. Since their impact force is lower, they are better suited for plastics or softer metals

Different types of dot peen marking technologies exist:

- Portable dot peen machines are easy to hold in one hand and allow operators to move around the shop and mark various items.

- Benchtop dot peen machines are ideal to engrave tags, plates, and similar items at a steady location.

- Integrated dot peen machines can be integrated in production lines to automatically mark parts without requiring human intervention.

Overview of Laser Marking Systems

While dot peen marking systems operate by mechanically hitting parts with a stylus, laser marking machines operate by changing part surfaces with laser light. A micro change in the surface texture or a localized heating of the part will change its visual aspect, creating markings that have a high contrast.

To sweep the laser over the material and create the marking, the beam is reflected using two mirrors whose orientations are controlled by a dedicated controller. Laser parameters can be optimized for each application to control the process with unmatched precision.

The most common types of laser systems used to mark parts are fiber lasers and CO2 lasers:

- Fiber lasers use an optical fiber cable to guide laser light with unmatched precision. The ones used for laser marking typically operate at 1064 nm, a wavelength that is ideal to mark metals, but also other materials like plastic or rubber. Fiber lasers have a compact design and can easily operate for over 10 years with minimal maintenance.

- CO2 lasers are less compact than fiber lasers and typically emit at a wavelength of 10.6 μm that is ideal to process organic materials like fabrics, cardboard, plastics, polymers and so on.

Like dot peen systems, laser machines can be integrated multiple ways:

- Tabletop lasers are ideal to engrave personal items such as jewelry and trophies.

- Laser workstations allow an operator to mark a steady flow of parts and automatically change the configuration for different types of parts. These stations can be moved around the shopfloor and are very efficient when equipped with a rotary table.

- Automated laser machines are meant for fully automated production lines that process a high volume of parts. They are quite common in smelting plants, casting plants, and assembly lines.

What is the Difference Between Dot Peen and Laser Marking?

The following 7 key points will help you understand whether dot peen or laser marking is best for your application.

1. Marking Quality and Contrast

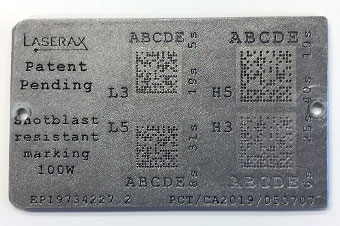

When it comes to marking quality and contrast, laser marking provides better results. The resolution is fixed by the laser beam size which can be easily modified, allowing markings with lots of details.

On the other hand, dot peen systems have a low contrast. Barcode readers often need special lighting conditions to read data matrix codes made by dot peening.

Dot peen systems tend to be inconsistent due to the mechanical process involved. As such, they contribute to a higher scrap rate. Marking quality is more consistent with laser markers.

2. Marking System Maintenance

All machines require maintenance, but some require it more than others. For laser marking, maintenance is minimal because the marking process is a non-contact one. Lasers require no consumables and process surfaces with laser light, so there is no mechanical wear between the laser and the part.

Dot peen systems are constantly stressed by shocks and vibrations. For this reason, they require regular maintenance. If there is a lack of maintenance, the marking quality diminishes, and the scrap rate increases.

3. Materials

Dot peen systems are typically used to mark rigid materials such as metals or hard plastics. These materials are common in the automotive and aeronautics industries, and so are dot peen systems.

Laser markers offer endless possibilities in terms of optical configuration. This important parametrization makes them effective for various materials such as metals (aluminum, stainless steel, etc.), ceramics, wood, plastics, and so on. Lasers are thus used in a wider range of industries.

4. Marking Applications

Dot peen systems are adequate for the writing of alphanumeric serial numbers or 2D barcodes, such as data matrix codes. However, they are not widely used for the writing of 1D barcodes. This is because 1D barcode readers need a higher level of writing contrast than 2D barcodes which cannot be achieved by dot peen marking.

Laser markers stand out with their ability to do different types of tracking codes and markings ranging from alphanumeric serial numbers to 2D barcodes. Laser marking can also be optimized to maintain a high readability rate after a range of surface treatments, including shotblasting, heat treating, powder coating, and e-coating. On the other hand, dot peen markings will most likely become unreadable if the production process involves post treatments.

Laser markers stand out with their ability to do different types of tracking codes and markings ranging from alphanumeric serial numbers to 2D barcodes. Laser marking can also be optimized to maintain a high readability rate after a range of surface treatments, including shotblasting, heat treating, powder coating, and e-coating. On the other hand, dot peen markings will most likely become unreadable if the production process involves post treatments.

Both dot peening and laser marking can be used for the deep marking of VIN numbers (also known as deep engraving), an important application in the automotive industry. For dot peen systems, the marking depth can be adjusted with the Z-axis of the stylus. For laser systems, the laser engraving process generates the energy required to dig deep into metals.

5. Cost Efficiency

The main advantage of dot peen systems is their initial low price compared to other marking methods. Typical solutions start at around $6,000, which makes them easy to fit in initial budgets.

Due to the mechanic contact between the dot peen system and the material, the writing tip deteriorates and must be replaced regularly. This leads to significant recurrent costs and constant maintenance.

The great flexibility offered by laser markers comes with a higher price tag. A typical laser marking system starts at $35,000 and up depending on the laser type and power required for the application. ,

Laser markers do not require additional or recurrent purchases and are low in maintenance, so they provide a better return on investment in the long term.

6. Marking Speed

In production lines, keeping up with cycle times is often a requirement. To ensure this, one thing you need to look at is the system’s marking speed.

Dot peen systems have a slow marking speed, making them less than ideal for many production lines. If time is not a concern however, they can do just fine.

In contrast, laser marking systems can meet the most challenging cycle times. This is because the laser’s power can be increased to process materials faster. For instance, a 100W laser works almost twice as fast as a 50W laser and can achieve high marking speeds.

If you are interested in learning more about how to meet cycle times for your production line, you should contact an expert.

Tell us about your application

7. Connectivity

When it comes to traceability, many manufacturers need to communicate the information to be marked from a centralized database to the marking system. Other manufacturers rely on standalone configurations that do not need to be connected to such a database.

All these options are made available through the system’s PLC and have little to do with the type of marking system. Laser markers and dot peen systems can both offer connectivity options. You just need to make sure that the communication protocol corresponds to your current installations (Ethernet/IP, PROFINET, RS-232, etc.).

Which Technology Fits Your Application?

Dot peen marking systems have been used for decades and remain an effective solution mainly because of their low purchase price and permanent markings. However, laser markers have become the go-to solution when a high performance is required, such as a superior density of information, or fast and easily readable markings.

- No use of consumables and low level of maintenance needed

- High speed marking with enhanced resolution

- High-quality contrasts allowing all types of barcodes

- Cost effective in the long run

If you are looking to get one of these marking systems to track your product, you might be interested in our eBook on Industrial Traceability: How Barcodes Work.

Tell Us About Your Application