If you are relatively new to laser technology, you are probably wondering what’s the difference between laser engraving and laser etching. And more importantly, which one is right for you.

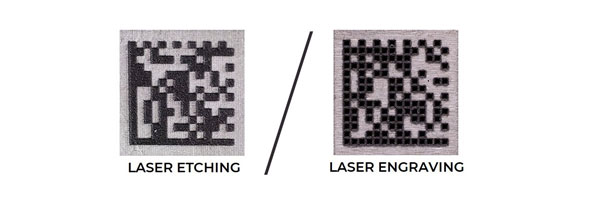

The main difference between laser etching and laser engraving is that etching melts the micro surface to create raised marks, whereas engraving removes material to create deep marks. Both processes use high heat to create permanent markings on metal surfaces.

Both processes are heavily used for part traceability. Let’s dive into each process to see which is best for which application.

The Laser Etching Process

When etching is performed, the laser heats and distorts the micro surface of the material. By doing so, the laser etched surface expands and creates a texture.

Laser etching creates black and white marks and is the most efficient process to permanently mark most types of materials. Etching is faster than engraving because it requires less energy from the laser beam.

You may need laser etching if:

- Your part is made of any metal, except stainless steel

- You want the fastest laser process

- You want a cost-effective laser that requires less laser power

- You need to integrate laser marking before non-abrasive treatments, including powder coating, e-coating, and heat treating

Watch the following video to see how fast our fiber lasers can etch the material’s surface. You will also see the high contrast that results from etching.

The Laser Engraving Process

Through the engraving method, the laser vaporizes a thin layer of the material to create a tracking code. This is done by sending a highly localized laser pulse onto your part.

Instead of creating a micro-surface that is raised above the material, laser engraving digs into the material. The engraving depth can reach up to 500 microns.

You may need laser engraving if:

- Your part is made of steel or aluminum

- You want marks with maximum durability

- You need to integrate laser marking before abrasive treatments, including shotblasting and sandblasting.

In the following video, black marks are created through deep laser engraving and the white background through etching.

Why Do You Need Laser Etching & Laser Engraving?

If you’ve tracked parts with dot peening, inkjet printing or printed labels in the past, you know that these marking technologies come with important maintenance and consumable costs. In addition, you’ve probably had to deal with inconsistent results due to an unreliable marking system.

How Etching and Engraving Solve Those Issues

- Laser direct part marking encodes information that cannot be detached from the product throughout its useful life.

- Laser marking has a high resolution; a lot of information can be packed in a very small area (especially if you’re using data matrix codes).

- Laser etching and laser engraving machines require very low maintenance.

- Fiber and CO2 laser systems require no consumables.

- Pulsed fiber lasers have a very low power consumption.

Which Industries Use Laser Etching & Engraving?

Many of our clients use laser etching and engraving to collect a wealth of information for their traceability program. Some of them also take advantage of this information to optimize their manufacturing processes.

They use these laser processes to mark all types of barcodes, including QR codes and data matrix codes, but also serial numbers and alphanumerical characters. Others also choose to mark their company logo onto the parts to brand their products.

Here are the most common industrial applications.

Automotive Industry

Car manufacturers have long required traceability of their suppliers. They were early adopters of the data matrix code as a way to uniquely identify parts going into the final assembly. The parts are scanned at crucial steps throughout the value chain to ensure conformity and enforce accountability. Nowadays, they require that part identification be performed as early as possible.

Read more about laser marking in the automotive industry.

Primary Metals Industry

Smelters, die casters, hot and cold roll plants and extruders came later in the game, mostly because of the requirements placed on them by their clients in the automotive industry. And they found out that the data they gathered from their internal traceability program helped them optimize their processes. Others used laser marking to manufacture products that meet strict environmental standards, differentiating themselves from their competitors.

Read more about laser marking in the metals industry.

Medical Device Manufacturers

The FDA has established strict regulations that require the identification of medical devices. It requires that most medical devices be identified with unique identifiers.

More information can be found on the Food and Drug Administration’s Unique Device Identification - UDI website.

Other Industrial Laser Marking Processes

Laser etching and laser engraving are not the only processes used in industrial applications. Laser annealing, although less common, is the only solution to mark stainless steel and chrome-plated workpieces.

The reason is simple: it’s the only process that creates permanent markings while maintaining the part’s natural resistance to corrosion.

Laser annealing heats the metal instead of engraving it. This process creates a black mark under the surface through a reaction known as oxidation.

The difference between annealing and etching is that annealing is a chemical reaction and that it does not melt the material’s surface. The difference is subtle to the eye.

Watch this video to see what we are talking about.

How Do You Integrate Laser Markers?

Laser etchers and engravers need to be optimized for specific applications. For this reason, you should talk to a laser expert to define your needs. With Laserax, you can either choose a turnkey laser machine or an OEM laser marker for a custom solution with a system integrator.

Tell Us About Your Application