Fiber lasers are ideal to engrave metal materials. If you don’t have the right information, choosing the right one will be challenging. But if you are willing to learn just the basics of fiber laser engraving, you can quickly identify the best laser engraver for your application.

In this article, you will learn everything you need to know. This includes the following topics:

- The Types of Fiber Laser Engravers

- Understanding Product Sheets

- Information to Gather Before Speaking with an Expert

- Advantages of Fiber Lasers for Metal Engraving

- Fiber Laser Technology: How It Works

The Types of Fiber Laser Engravers

There are two main categories of fiber laser engravers: manual and automated.

With the manual, parts are loaded and fixed manually, and you have a choice of four types: desktop lasers, basic workstations, rotary workstations, and door workstations.

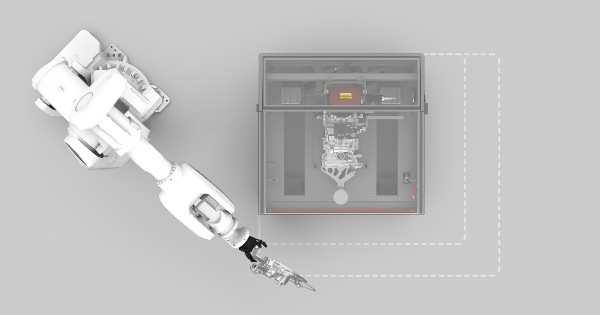

Automated fiber laser engraving machines are a favored option for high-volume production lines.

Desktop Lasers

Desktop (also called tabletop) fiber laser engravers are designed for low-volume production and small parts. They are ideal for DIY hobbyists and small businesses. These lasers typically start at around $5,000, and higher quality units will cost up to $25,000. Lower quality units are usually fragile and offer no protection for the laser.

Basic Workstations

Manually loaded laser marking workstations like the Flex are entry level solutions for industrial applications. They are designed with robust components, and the laser beam is fully enclosed to ensure safety. These stations start at $120,000 and operate on a 20-30W laser. Unlike rotary-table workstations, they are used when a fast cycle time is not required.

Rotary Table Workstations

Workstations like the Rotary start at $230,000. They are meant to minimize idle time of operators using it, who can load parts on the rotary table while another part is being marked. These machines are typically equipped with a high-power laser (at least 50W) to meet shorter cycle time requirements.

Door Workstations

For large parts like die-castings, larger workstations are needed. With the Automated Door Workstation for example, parts are loaded through a sliding door, and the size of the workstation can be adapted to fit the part’s dimension. This type of workstation is made with industrial grade components to withstand harsh environments and usually starts at $160,000.

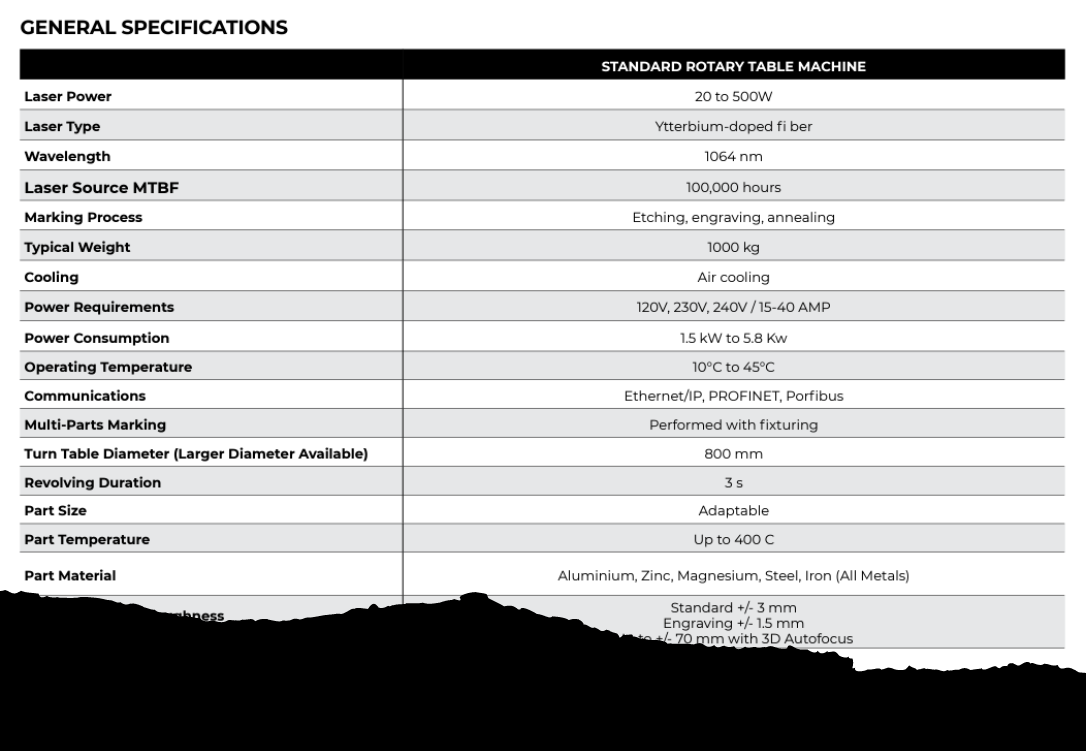

Understanding Product Sheets

Product sheets help you understand the capabilities of the laser. They provide valuable information such as materials that can be engraved, safety features, software compatibilities, and application examples. They can be used to quickly evaluate whether the laser will meet your needs and requirements.

Fiber Laser Source (Wavelength)

The laser source includes an optical fiber which can be doped with different rare-earth elements to generate specific wavelengths. By knowing the laser source and its wavelength, you can quickly know if a fiber laser is right for your application. Let’s look at common examples:

- Ytterbium-doped fiber lasers produce a wavelength of 1064 nm, which makes them ideal for the material processing of metals. These are the fiber lasers that Laserax uses for metal marking and cleaning applications.

- Thulium-doped fiber lasers produce a wavelength of 1940 nm and can be used for medical applications as well as for laser marking plastics.

- Erbium-doped fiber lasers produce a wavelength of 1550 nm and are mainly used in telecommunications. They provide us with high-speed internet and voice over IP but are not used for laser engraving.

The use of fiber lasers is widespread due to the various wavelengths they can generate. The first step should be to look up the laser source to see if it is compatible with your application. This could prevent you from buying a laser that cannot engrave your material.

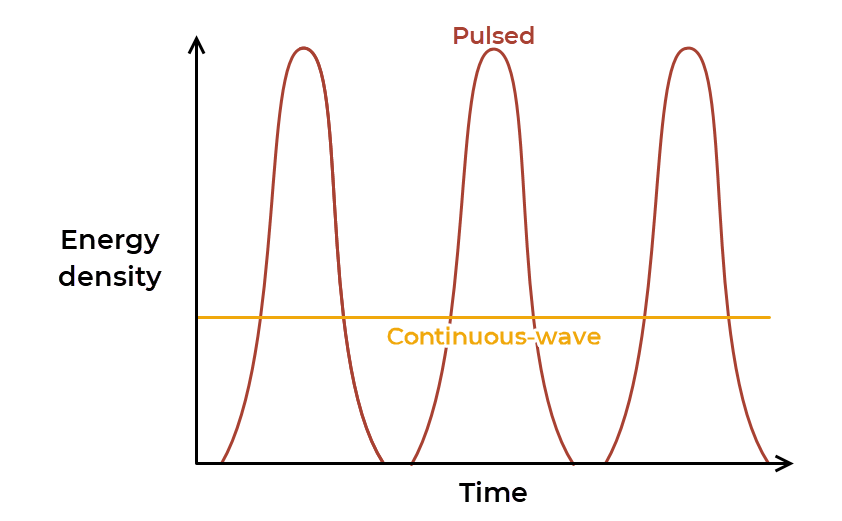

Pulsed vs. Continuous

When buying a laser, you must look at whether the laser beam is pulsed or continuous.

Let’s look at the types of beams more closely:

- Pulsed beams generate high energy peaks that are ideal to engrave permanent marks or pierce small holes without melting surrounding areas.

- Continuous-wave beams generate consistent energy levels that are perfect for laser welding, laser drilling and laser cutting machines.

Lens Configuration and Laser Parameters

Laser experts can optimize the lens configuration and laser parameters for different materials and manufacturing processes. The lens configuration includes the focal length, scanning speed, spot size, marking distance, and so on. Laser parameters include the beam diameter, beam quality, pulse length, the number of passes and much more.

At Laserax, we offer different configurations for our ytterbium-doped fiber lasers depending on the metal that needs to be engraved. If you’re interested in knowing how laser parameters affect the laser process, you can read this article on laser ablation.

Laser Power

To know how much laser power you need, you first need to know your desired cycle time (such as the number of parts per minute) for the laser marking operation. The more powerful the laser, the faster the processing. If you are bound by short cycle times, high-power lasers (100-500W) represent a good investment. Otherwise, you can usually opt for a low-power laser (20-30W).

Apart from the power, other factors affect the engraving time. These include:

- The font used for text and serial numbers

- The size of the engraving area

- The material that needs to be engraved (for example, aluminum is easier to engrave than steel)

- The background color of barcodes, data matrix codes and QR codes (for example, a pale background improves contrast but requires additional time)

- The marking process (for example, the deep engraving of VIN numbers requires more time)

Time estimates for laser engraving can give you a rough idea of the laser power you need. But since many factors affect the engraving speed, you usually need to talk to an expert to determine the exact power needed for your application.

Based on your time requirements, Laserax can offer up to 500W to meet challenging cycle times. A 100W laser marker is usually enough to meet the time requirements of most industrial applications.

Working Area

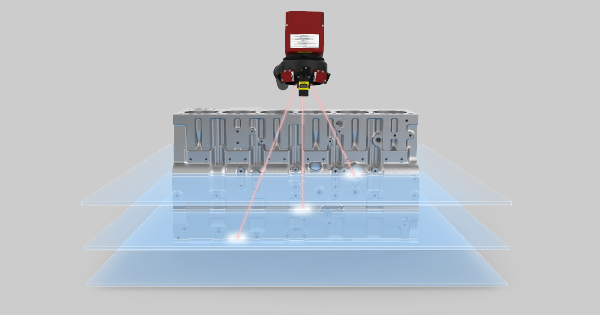

The working area is the size of the area within which the laser can perform engraving. Lasers can only engrave parts that are within their field of view, but they can be mounted on gantry systems to increase the size of the working area. A gantry system is necessary when the laser must engrave outside its field of view. It operates like an automated CNC.

Laser Safety

Without a certification, fiber laser engravers are considered class-4 lasers. This means that the laser beam and its reflections can cause eye injuries, skin burns, and fires. The dust and fumes generated during laser engraving can also be dangerous for workers. Getting a certified laser is essential to protect workers against laser hazards.

Certified Lasers

When you buy a laser, you need to know if it is a certified class-1 laser product. Several organizations regulate laser products all over the world, but the most trustworthy certifications are ANSI Z136.1, FDA CFR 1040-10, and IEC 60825.

With products following these standards, you don’t need any additional laser safety measures. The beam and its reflections are completely enclosed, and fumes are extracted from the work area.

Uncertified Lasers

Uncertified lasers are not safe for use without adequate safety measures. Desktop lasers, for examples, rarely have an enclosure to protect workers from the beam. The most important safety measures include:

- Following a laser safety training

- Wearing laser safety glasses

- Activating light warnings when the laser is being used

- Restricting access to the laser

To restrict access to the laser, you can enclose it in a room. Or, you can use warning tape to properly identify the nominal hazard zone (i.e., the zone where the beam and its reflections can be dangerous). The laser manufacturer can provide you this information.

Software

Each laser engraving machine has its own specialized software. For this reason, when you choose a laser engraver, you need to make sure that the embedded software meets your needs.

Here are common examples of applications and how they dictate your needs:

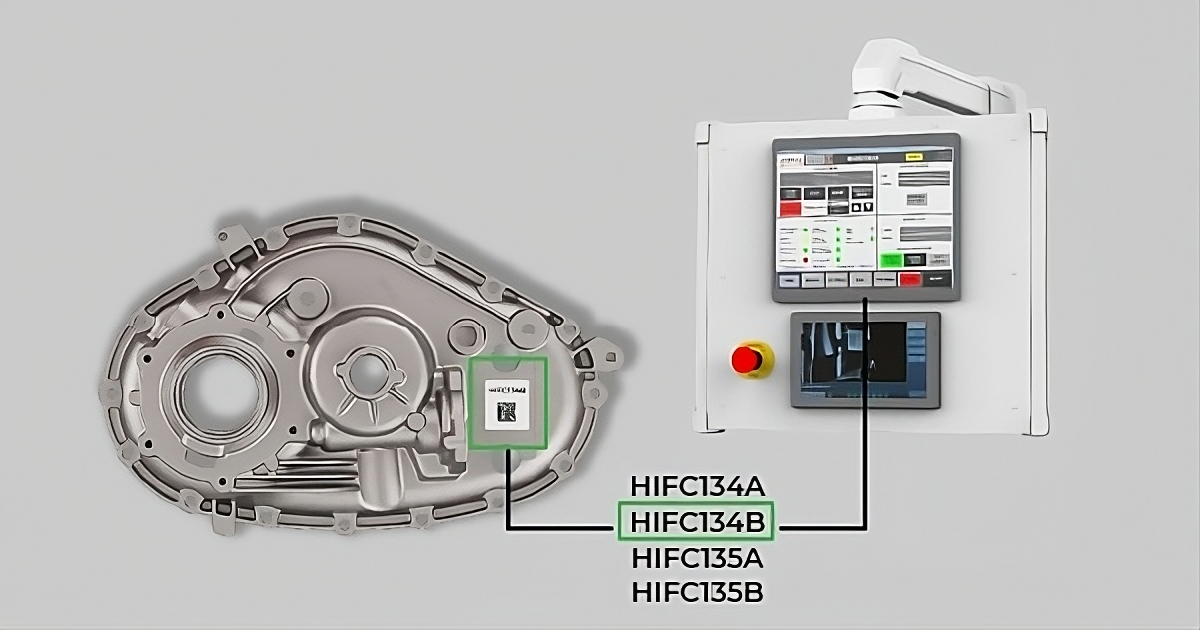

Traceability of a Single or Few Part Models

If you need to identify a few part models for traceability, you need basic software capabilities to mark data matrix codes, QR codes, serial numbers, and logos. This is often the case in high-volume production lines producing the same part model with a few variations. The used interface doesn’t need to offer advanced functionalities because the traceability information is often updated automatically through a central database.

Traceability of a Variety of Parts

If you frequently change the type of part you are marking, you need more advanced software capabilities and an easy-to-use interface. The software should be connected to a vision system to detect parts and display them visually on the user interface. You should be able to easily enter new traceability information, such as by touching the screen where you want to add the identifier.

Custom Engravings

If you’re a small business that wants to engrave drawings and logos on items like jewelry, guns, and trophies, you need an easy-to-use software centered around graphics. You want to be able to import photos and drawings, and simply drag and drop them onto the part.

Autofocus Technology

Autofocus technology uses vision to detect variations in part positioning and adjust the laser focus accordingly. This ensures that the engraving process is always optimal.

It is required when parts cannot be positioned accurately, when different part models are used, or when surfaces are highly curved.

Information to Gather Before Speaking with an Expert

Before speaking with an expert, it’s best to gather information about your manufacturing process. The following considerations will help determine which type of system you need, but also how it needs to be configured.

- List the materials that need to be engraved. Although a wide variety of metals can be marked with fiber lasers (such as aluminum, steel and stainless steel), each alloy has unique properties that affect how the laser beam interacts with the surface.

- Determine the information that needs to be marked or encoded. This may include the weight, part number, mold number, date and time, and so on.

- Determine the types of markings. These may include text, alphanumerical characters, logos and codes like data matrix codes.

- Determine how much time is available for marking. Even a rough estimate is useful in finding the right laser power.

- Identify which laser options meet your needs. Laser engraving solutions can include a laser safety enclosure, an HMI to easily adjust the laser for different operations, a dust extraction system, an air knife to prevent dust accumulation on the lens, and much more.

- Identify the IP rating that you need. This is dictated by the environment where the fiber laser marking machine is integrated. Casting plants, for example, require a higher protection level than assembly lines. Some lasers have better protection against dust and liquid projections.

- Identify the electrical certifications required in your country. Like any electrical equipment, if the laser fails to meet these requirements, you could be forbidden from installing it. For example, the “UL” certification is in place in the USA; the “CE” in Europe; and the “CSA” in Canada.

Advantages of Fiber Lasers for Metal Engraving

Fiber lasers are not the only option for metal engraving. Other types of lasers (such as Nd:YAG lasers) can produce similar wavelengths and hence be used for the same applications.

Why choose a fiber laser then?

Different lasers can be configured differently and offer unique advantages. Fiber lasers offer the following advantages:

- Optical fibers offer a better beam quality (better focused) due to their light guiding properties. As a result, fiber lasers are more efficient when engraving metals.

- They have a low power consumption and small heat management requirement.

- They are compact.

- They have a low cost of ownership as well as low maintenance requirements, which makes them ideal for automated production lines. Manufacturers don’t need to have them recalibrated to maintain their efficiency over time.

- The laser source has a high mean time between failure (100,000 hours). This means that fiber lasers can operate full time for more than 10 years with the same high-quality results.

Fiber Laser Technology: How It Works

Understanding fiber laser technology can help you make a more informed decision when buying a laser. To explain how each component works, let’s go over the journey of a laser beam, starting in the laser diodes, going through optical fiber, then finally hitting the part to be engraved.

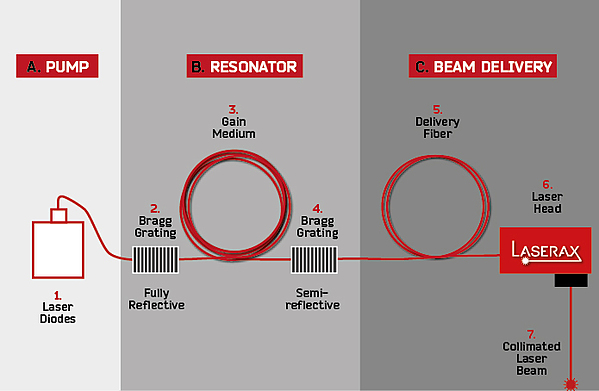

A. The Pump Module

The laser beam journey begins when the laser diodes emit light. Light travels through the fiber optics and reaches the gain medium, pumping it with photons which, in turn, excite the photons already in the gain medium. This generates an energy buildup.

B. The Resonator Module

When the photons enter the resonator module, they bounce back and forth between two Bragg gratings. A Bragg grating is a piece of fiber optics with lower-density stripes in it that control which wavelengths are reflected and which are not. It acts as a selective mirror.

One of the Bragg gratings is semi-reflective, meaning that only the photons of specific wavelengths go through. These photons form the laser beam. For our ytterbium-doped fiber lasers, only the photons with a wavelength of 1064 nm go through.

C. The Beam Delivery

Before the laser beam generates a permanent mark onto the part surface, it goes through a lens and, sometimes, a beam expander—both of which are located inside the laser head.

The lens focuses the beam onto a single location, allowing it to generate enough energy for engraving. The beam expander, on the other hand, expands the size of the beam (usually referred to as the spot size).

A larger beam tolerates part positioning variations better, preventing adjustments between two jobs. Most fiber lasers have a low tolerance for part positioning variations. If a large tolerance is important for your application, make sure to inquire about the laser’s tolerance when choosing a fiber laser.

Fiber lasers direct the beam to a specific location on the part using mirrors. These mirrors are controlled using “galvanometer motors” (or galvos), a special type of motor that can move the laser beam very precisely and at a high speed. For this reason, fiber lasers are sometimes called galvo laser engravers.

After leaving the laser head, the beam ends its engraving journey when it hits the surface.

The Final Step: Choosing a Laser

When the time comes to choose, it’s best to run sample tests with different companies. This will allow you to make an informed decision and choose the best fiber laser for your application.

If you’re interested in learning more about our products, you can go through our range of laser engraving machines (for turnkey solutions) as well as our OEM laser markers (for custom solutions with system integrators).